Stanford’s Robot Makers: David Lentink

David Lentink is an assistant professor of mechanical engineering at Stanford University. His lab is known for its work on aerial vehicles – drones and winged robots – that are inspired by birds, bats and flying insects. This Q&A is one of five featuring Stanford faculty who work on robots as part of the project Stanford’s Robotics Legacy.

What inspired you to take an interest in robots?

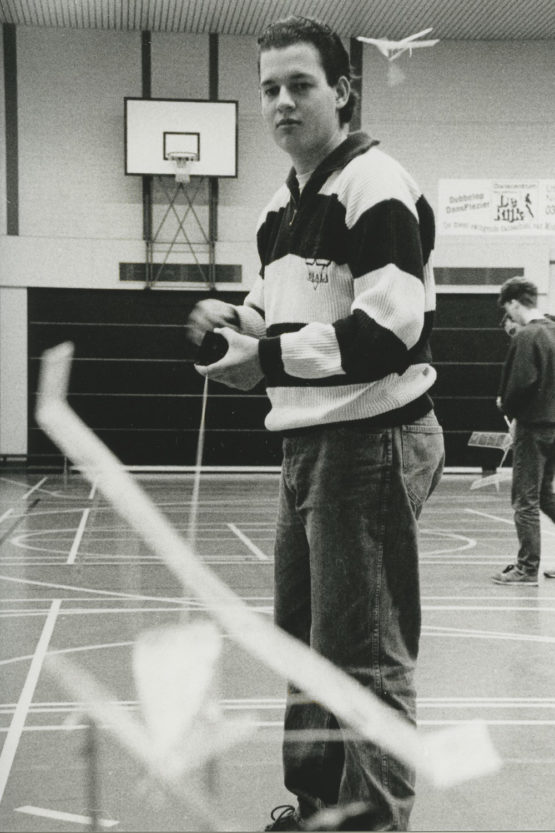

Lentink as a high-schooler, winding the rubber band of his model airplane with another flying in the background, circa 1994. (Image credit: Courtesy David Lentink)

I designed and built model airplanes at high school and set flight duration records in competition. The rubber-powered airplanes I designed then were passively stable – they had to fly on their own without any computer onboard – so the design had to be just right. They could fly up to 18 minutes on a single rubber band. (I did not compete in world championships, but plan to pick it up again when I am 70 years old, because that is the ideal age to become world champion in it!)

I also started building flapping model airplanes powered by rubber bands. From this hobby, I learned robots could do so much more if you build in the dynamics that they need to perform well passively. Then you can focus the limited onboard control on what matters most to complete a mission.

This lesson has proven a real advantage because I don’t get bogged down by dogmas requiring impossible computational power. It has also helped me question the conventional wisdom that unstable aerial robots that are constantly controlled by an autopilot are most maneuverable. More important, the instability of robots may be a key factor that is limiting them from flying well in turbulence, such as gusts of wind in urban environments.

What was your first robotics project?

My first project was the DelFly project, which I initiated as a PhD student in Delft based on my aerodynamics research of insect flight at Caltech. I discovered that insect aerodynamics was scalable to the scale of robots, which meant I could use standard motors, batteries and radio control components and make robots fly like insects for a couple thousand dollars instead of a million. (This is what people were spending on it in 2005, without success.)

My team, which included 10 undergraduates, and I worked on a flapping robot that could vertically take off and land like an insect many times. It was based on the world’s worst actuators and remote control electronics, because everything had to be tiny and lightweight. The design was way too slow and imprecise for such a dynamic maneuver in the books of a control’s engineer. Thanks to the well-designed passive dynamics, the robot could pull off a vertical take-off and landing maneuver as many times as we liked – as many as 19 times in one video.

Along the way I had to convince the students to ignore all the advice on making the robot unstable, which they received from control’s engineers work based on aircraft design. To succeed, you have to find ways to cope with the many paradigms in different fields and shift them one by one.

Thinking back, what did you hope robots would be doing in the “future”?

When I first was getting into the aerial robotics, I was hoping we could fly like animals do. I was fascinated by how birds fly and maneuver in a fashion that seemed effortless. For example, I asked my professor at Delft if he knew why my ornithopters did not need a vertical tail – same as birds and insects – and he didn’t know. He said it would be a great research question. (Now, a student in my lab measured it this past summer and we much better understand than when I started as a student.)

As a student, I was also inspired by the amazing stop-motion photos of insects and birds made by Stephen Dalton and John Brackenbury. Whereas the birds in flight were instantly appealing to me, the photos of the insects transformed my thinking. I still don’t like insects, but insects in flight look incredible; they are like beautiful aerial ballet dancers with their wings spread, generating lift and thrust. It inspired me to develop insect-inspired robots with students.

But I always craved going back to birds. They are less accessible to engineers – and rightfully so – due to additional levels of regulations for working with vertebrates. So, after my BS and MS in aerospace engineering, I became a biologist during my PhD. As an engineer and biologist I can study birds up close with my students and use that inspiration to design aerial robots that fly like birds.

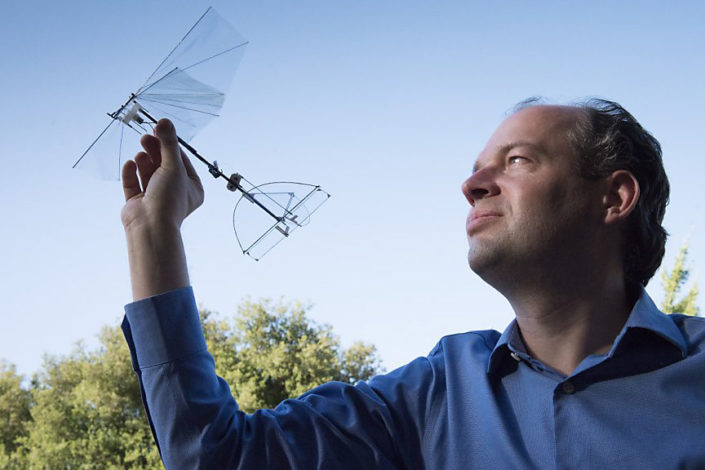

Lentink during his undergraduate work in 1999, holding a super-lightweight ornithopter with flapping wings. (Image credit: Courtesy David Lentink)

Lentink, in 2013, holds an example of the models his students made to simulate birds in flight. (Image credit: L.A. Cicero)

Now, I am excited about the economic potential of aerial robot delivery. I do think some company will transform the way we move goods around the planet and deliver them rapidly and efficiently and I think that will serve our economy well.

My other passion is the potential of aerial robots to perform search and rescue during natural disasters. Current drones cannot meet that challenge – they are still too unsafe, too noisy and fly too short of distances. Weather, especially precipitation and turbulent gusts, are open challenges. That is why I study birds – they outperform aerial robots with a large margin and can fly most of the time. For example, the 300-gram bar-tailed godwit can fly 11,700 km from Alaska to New Zealand and the 40-gram common swift can fly without landing for nine months, catching insects, scooping water and sleeping on the wing.

What are you working on now related to robotics?

With my lab, I am studying how birds fly and, integrating our findings, we are developing better flying autonomous robots. Our biggest current effort is to make robots fly better in turbulence.

I also collaborate with Mark Cutkosky and a student we co-advise, Will Roderick, on new passive mechanisms to enable robots to perch on a wide range of natural surfaces. Basically, we want to fly anywhere and land anywhere, regardless of turbulence and regardless of the complexity of perching surfaces. Both these aerial robot performance aspects are essential for efficient aerial delivery and search and rescue.

Ever since my DelFly, I have further pursued learning deeply in many areas to accomplish something new and unexpected. Like developing a $10,000 robot with undergraduates that outperforms all the expensive ones developed by PhD students, postdocs and experienced engineers. A big part of the success comes from students believing they can do anything and them not being bogged down by too much knowledge.

How have the big-picture goals or trends of robotics changed in the time that you’ve been in this field?

I have largely avoided following trends because so many of them are focused on short-term advances. Also, by defining our own area of research we can focus more on collaborating with other labs instead of competing.

Currently, I have the only engineering lab with a bird wind tunnel to decipher the physical mechanisms that enable birds to outperform aerial robots. It is next-level bio-inspired design, because my engineers understand both the biology and the aerial robot application.

All our work is interdisciplinary and that is something we see more and more in other labs. I really like our high level of integration and collaboration in the lab because I think a PhD is best done together. My students are all experts in different areas and, in their joint office, they sit and talk with experts in other areas. This group culture has enabled each of them to pursue work they could have never accomplished as well on their own.

We learn a ton together and make frequent discoveries about how birds fly to build these new robots, which usually inspire new questions. It is a passionate cycle of scientific discovery and invention. Thanks to my students I am engaged in several areas of research at the deepest level too. It is what I am in research for. I love learning new stuff and making discoveries together.